Circularity is Lean 2.0

The Next Systematic Competitive Advantage

After introducing Circudynamics last week, I've been asked by several readers about the business case for circular transformation. Leaders want to understand not just the methodology, but why they should invest precious resources in what many see as sustainability theater. That's why I'm writing my second Circudyne Letter piece on Circularity is Lean 2.0: The Next Systematic Competitive Advantage. The most compelling way to understand circular transformation's business potential is through the lens of the last systematic transformation that separated market winners from losers—Lean principles in the 1980s-1990s.

The Toyota story is one of the great transformation stories. Over time, the common conception of it has been distilled down to: they had quality problems, which led to heightened costs from rework. They invented and implemented the precursor to what would become known as Lean. Quality improved. Costs went down. Simple operational improvement.

There’s nothing wrong with this memory. But it doesn’t capture the full story. And in that full story lies the key to major opportunities today, even after the era of Lean transformation has come and gone.

Toyota did have a waste problem. This waste manifested in two ways: high costs from inefficiency and rework, plus low quality that limited market access. The Toyota Production Method was created to address both systematically.

Toyota justified the transformation by promising to capture quantitative benefits—the cost savings from eliminating waste and inefficiency. But enormous benefits flowed from the qualitative benefits that followed. When Toyota achieved superior quality, it opened new markets. "Made in Japan" went from epithet to signifier of excellence, freeing Toyota to move upmarket into luxury categories and fundamentally reshape global automotive competition.

Today, many leaders remain skeptical of circular transformation because they see it as a sustainability cost center, not the source of competitive advantage. They've watched companies spend millions on circular initiatives that deliver modest environmental gains while adding operational complexity.

This is the mistake skeptics made about Lean in the 1980s. Circular transformation offers more than mere operational improvement. It's about systematic reorganization around different principles of value creation that generates sustained competitive advantage.

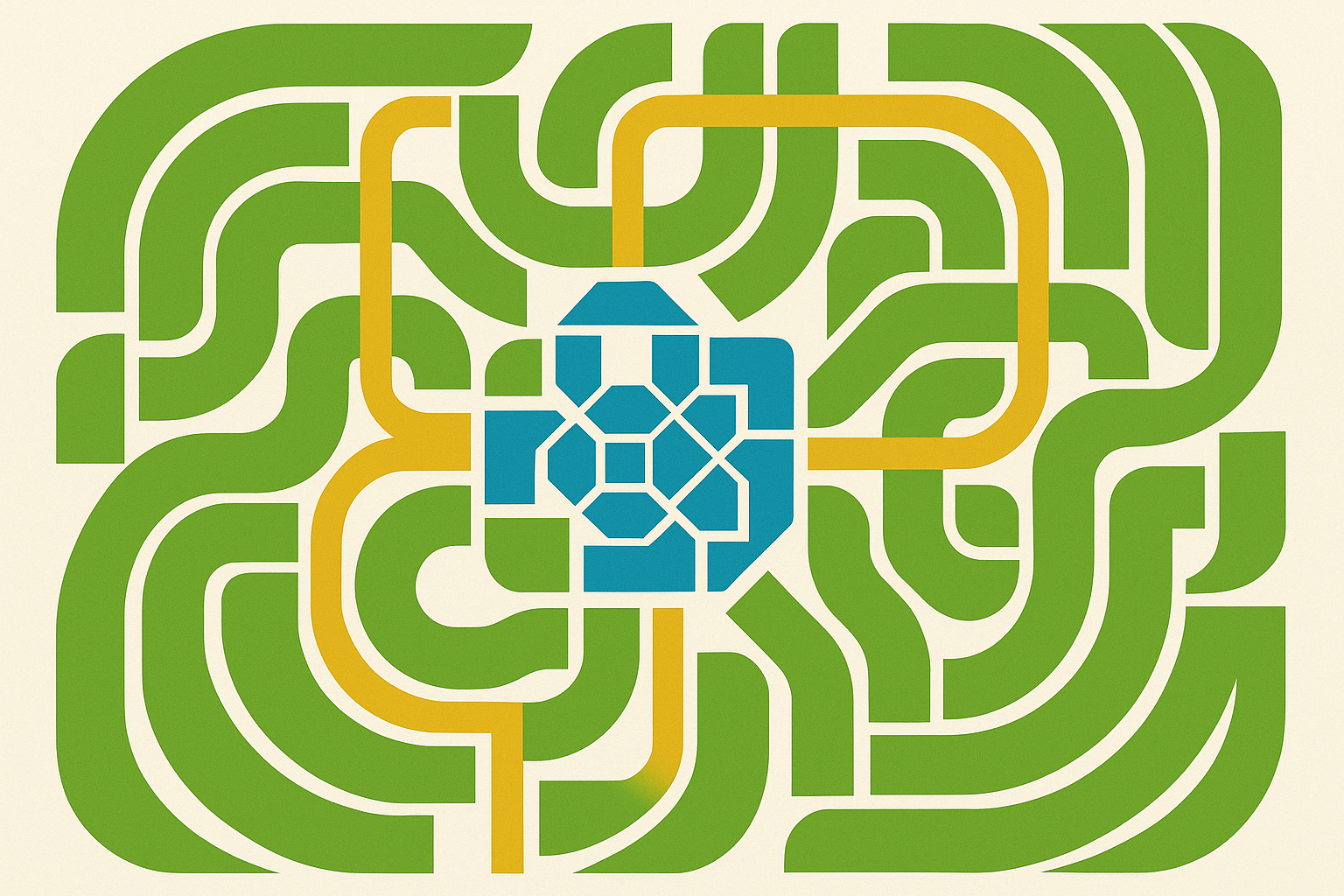

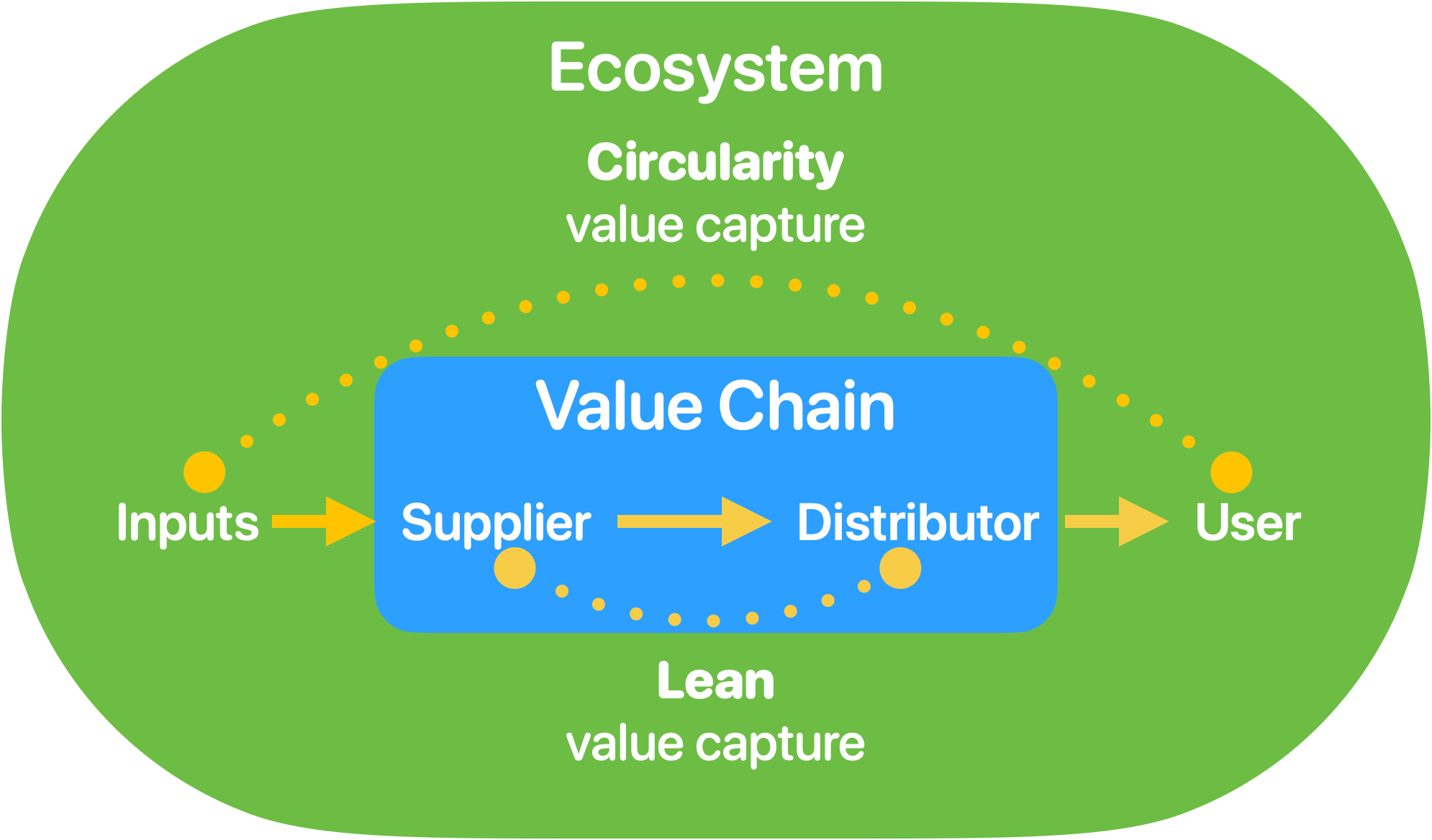

The linear economy is currently where we live, and it has a waste problem. Linear business models ignore waste that circular models acknowledge and address systematically. Circular models define the ecosystem more broadly than the traditional value chain. Lean addressed internal waste systematically, and external waste incidentally. Circular transformation takes a systematic approach to ALL waste—inside the value chain and beyond.

By architecture and philosophy alone, circular transformation is "Lean 2.0”. It applies the same systematic thinking—but expands the scope.

Circular transformation inverts Toyota's recipe while using the same ingredients. Toyota's sequence: quantitative justification (cost savings) led to qualitative benefits (quality) that enabled market transformation. Circular transformation sequence: qualitative justification leads, then quantitative benefits follow in proportion to ecosystem integration level.

The scope advantage is enormous. Lean optimized value chains within enterprise boundaries. Circular transformation optimizes entire ecosystems. More waste to eliminate means more opportunity for systematic competitive advantage.

Circular transformation is new, but the experience with Lean provides decades of data proving the transformative benefits of systems-minded leadership.

The rest of this essay covers the proven second-order effects that made Lean transformation profitable beyond operational improvements, plus implementation guidance for different leadership types and the discovery process that makes circular transformation successful.

Subscribe to continue reading